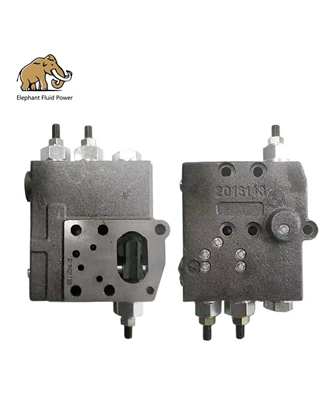

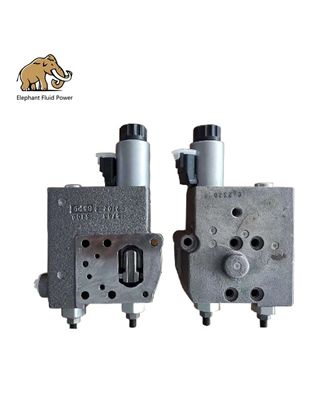

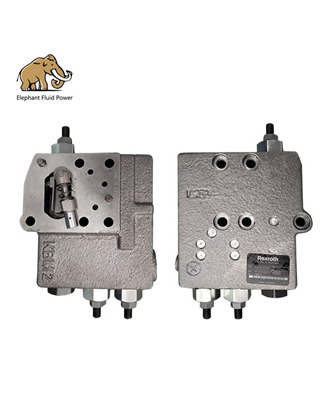

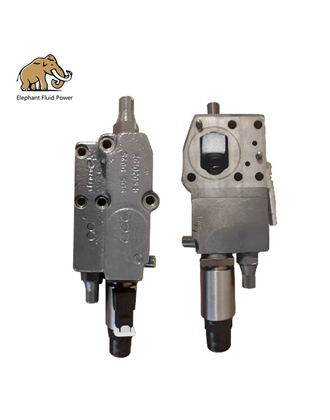

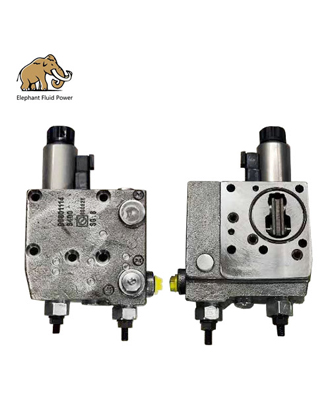

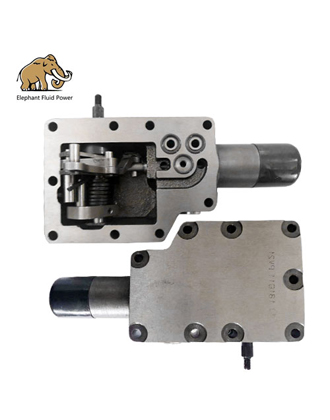

Control Valves

Control valves are another type of component that can be found in hydraulic systems. These valves help regulate and direct the flow of fluid through the system. Depending on the type and their design, they can alter the size of the passages the fluid can flow through, alter the pressure in the system, alter the direction of flow, and alter flow rates. There are three general types of control valves:

• Flow Control Valves: This valve regulates fluid flow rates by automatically altering the size of the openings within the valve the fluid will flow through.

• Direction Control Valves: This valve ensures fluid is moving in the desired direction. Some styles are referred to as check valves and keep fluid moving in one direction while preventing it from flowing backward.

• Pressure Control Valves: This valve controls, switches, and regulates the desired pressure, which can be altered by making adjustments to the valve.

Each type of control valve is available in various configurations to work with various systems, from inline to flanged and sub-plate mounting options, based on where they are required in the system. Based on their placement, the control valves will operate differently and provide various functions.

Control valves can be controlled electronically or manually, depending on the complexity of the system. The positioning of the valves can be regulated by other attached components, in addition to actuators, and it may include temperature gauges, flow meters, and so on.

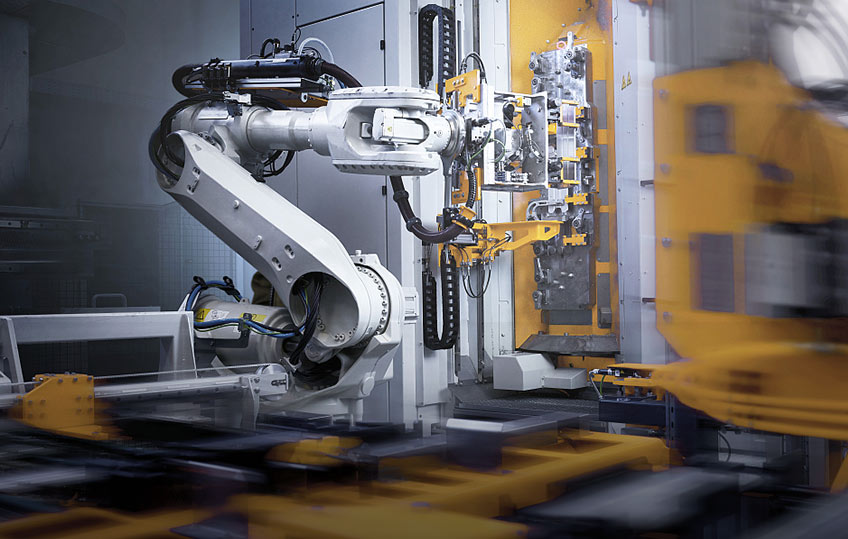

Control valves can be found in numerous types of hydraulic systems, as well as used alongside various pumps, including piston pumps in hydraulic braking systems, printing presses, construction equipment, and so on.

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu