The A10VSO series pumps are axial piston variable displacement pumps widely used in various hydraulic systems. In China, many hydraulic component manufacturers produce this pump to meet the needs of the domestic market. This article will provide an in-depth analysis of the A10VSO series pumps made in China, including its structure, working principle, common faults and maintenance.

The main components of the A10VSO series pumps include

Cylinder body accommodates the piston and cylinder barrel and withstands high pressure.

Swash plate controls the angle of the piston and adjusts the output of the oil pump.

Flow plate guides the flow direction of hydraulic oil.

Piston and shoe assembly converts the rotational motion of the swash plate into linear motion of the piston.

Bearing assembly supports rotating parts and reduces friction.

Shaft transmits power.

Seal prevents internal leakage.

Working principle

By rotating the swash plate, the relative position between the piston and the cylinder barrel is changed, thereby changing the output flow and pressure of the pump. The flow plate controls the inflow and outflow direction of the hydraulic oil.

Common faults and causes

Leakage aging and damage of seals, wear of cylinders, wear of distribution plates, etc.

Excessive noise bearing damage, gear wear, cavitation, foreign matter entering the pump body, etc.

Insufficient flow or insufficient pressure swash plate stuck, distribution plate wear, oil suction line blockage, hydraulic oil pollution, etc.

Overheating hydraulic oil viscosity is too high, cooling system failure, excessive load, etc.

Maintenance steps

Disassembly cut off the power supply, release the pressure, and disassemble the pump body in sequence.

Cleaning Use detergent and compressed air to thoroughly clean each component.

Inspection Check the wear and measure the clearance.

Replacement Replace damaged parts.

Assembly Assemble in sequence, pay attention to the tightening torque.

Debugging Connect the pipeline, inject hydraulic oil, start at low speed, and gradually increase the speed and pressure.

Maintenance precautions

Professionalism Maintenance requires professional knowledge and skills.

Special tools Use professional tools.

Spare parts quality Replace original or certified spare parts.

Cleanliness Keep the environment and parts clean.

Careful commissioning Ensure that the pump performance meets the requirements.

Maintenance recommendations

Regular maintenance Regularly replace hydraulic oil and check the filter.

Avoid overload Avoid long-term overload operation of the pump.

Pay attention to cooling Ensure that the pump has good cooling conditions.

Professional maintenance Regular inspection and maintenance by professionals.

Features of A10VSO series pumps made in China

Price advantage Compared with imported brands, the price is more competitive.

Short delivery cycle Meet the domestic market's demand for delivery speed.

Perfect technical support Many domestic hydraulic equipment manufacturers provide perfect technical support.

Product quality varies Due to the large number of manufacturers, there are differences in product quality.

Purchase recommendations

Choose a qualified manufacturer Choose a manufacturer with production qualifications and a good reputation.

Understand product parameters Understand the flow, pressure, speed and other parameters of the pump in detail to ensure that it meets the use requirements.

Request relevant certificates Request product certificates, test reports, etc.

After-sales service Understand the manufacturer's after-sales service policy to ensure timely support during use.

Summary

The A10VSO series pumps made in China occupy an important position in the domestic market. Their price advantage and short delivery cycle are favored by users. However, when choosing and using them, you need to pay attention to the differences in product quality and choose reliable suppliers.

Performance comparison of A10VSO pumps made in China from different brands

How to choose the A10VSO pump suitable for your application

Common failure case analysis of A10VSO pumps

Maintenance and maintenance tips for A10VSO pumps

Future development trend of A10VSO pumps

If you are interested in these issues, please feel free to ask.

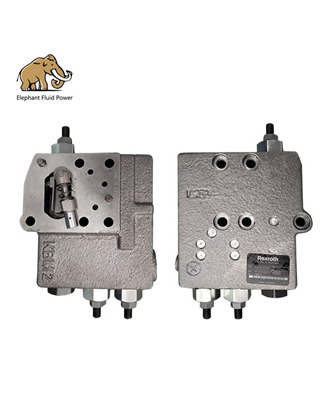

Elephant Fluid Power specializes in the production of

Rexroth A2F, A2FM.A2FE, A2FO, A10VO, A4VSO, A4VTG, A4VG, A11VO series

Sauer SPV, MF, 90R, 90L, 90, KRR, FRR, JRR, ERR, MPV, MPT series

Kawasaki K3V, K5V series

Parker F11, F12

NACHI PVD-0B, PVD-00B, PVD-1B, PVD-2B, PVD-3B series

Elephant Fluid Power is a leading manufacturer and distributor of hydraulic components, we produce the most complete hydraulic motor, hydraulic steering unit, directional control valve, gear pump, piston pump, vane pump, spare parts, etc.

We are committed to creating the highest end quality and after-sales service.

www.heavyequipmentmaintain.com

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu