Piston pump is an important device in hydraulic system. The hydraulic cylinder is powered by hydraulic pressure, and the hydraulic cylinder pushes the conveying cylinder and outputs the material in the conveying cylinder to the pipeline. It relies on the reciprocating motion of the plunger in the cylinder body to change the volume of the sealed working chamber to achieve oil absorption and oil pressure. It is widely used in occasions where high pressure, large flow and flow need to be adjusted, such as hydraulic presses, construction machinery and ships, in sewage treatment, solid waste treatment, mining and metallurgy, dredging, dredging, petrochemical, power plants, cement industry and other fields Also very broad. So why can it be widely used?

Because hydraulic piston pump spare parts do not require external energy, only the force of the flowing water provides them with the energy they need. Their device is extremely simple, with only two moving parts. It is a kind of reciprocating pump, which belongs to the volume pump. Its piston is driven by the eccentric rotation of the pump shaft to reciprocate, and its suction and discharge valves are all one-way valves. When the piston is pulled outward, the pressure in the working chamber decreases and the outlet valve closes. When it is lower than the inlet pressure, the inlet valve opens and the liquid enters; when the piston is pushed inward, the working chamber pressure rises and the inlet valve closes. When the pressure is higher than the outlet pressure, the outlet valve opens. The valve opens and the liquid drains. When the drive shaft drives the cylinder to rotate, the swash plate pulls or pushes the piston out of the cylinder to complete the oil suction and discharge process. The oil in the working cavity formed by the piston and the cylinder hole is communicated with the suction and discharge cavities of the pump respectively through the oil distribution plate. The variable mechanism is used to change the inclination of the swash plate, and the displacement of the pump can be changed by adjusting the inclination of the swash plate. The total stroke of the reciprocating motion of the piston pump piston is unchanged, which is determined by the lift of the cam. The amount of oil supplied to the plunger per cycle depends on the oil supply stroke, which is variable without being controlled by the camshaft. The start time of fuel supply does not change with the change of fuel supply stroke. Rotating the plunger changes the timing of the end of fuel supply and thus the amount of fuel supplied. When the plunger pump is working, under the action of the cam on the camshaft of the fuel injection pump and the plunger spring, the plunger is forced to reciprocate up and down to complete the oil pumping task.

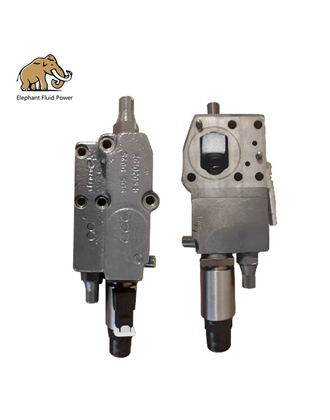

In order to make the products more suitable for people's use scenarios, Elephant Fluid Power Co., Ltd. also reduces the operating noise of the piston pump to a lower level on the basis of the advantages of high rated pressure, compact structure, high efficiency and convenient flow adjustment. Low (less than 80 decibels), their hydraulic piston pumps run more stably, and because of the business philosophy, the pricing is also low. If many big brands of hydraulic piston pumps need to be replaced, they can be purchased directly from Elephant Hydraulic Company. Their products are the most complete and can be perfectly interchanged with all brands of piston pumps. Not only hydraulic pump for sale, but also hydraulic motors, hydraulic reducers, etc. can be provided.

how does a piston pump work

how does a hydraulic pump work

how a hydraulic piston pump works

what is hydraulic pump

types of hydraulic piston pumps

hydraulic pump working video

piston pump working principle pdf

hydraulic pump diagram

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu