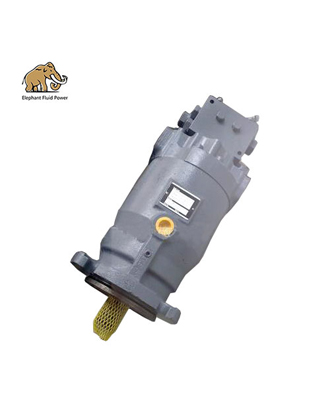

When some customers use the hydraulic piston pump purchased from Elephant Hydraulic Company, they may find that there are some large and small problems with the pump. At this time, everyone will suspect that the real object of Elephant Fluid Power does not match the propaganda, because we promised the pump. Excellent quality and long life. But the editor would like to tell you that the service life of the piston pump is not only about the quality. According to relevant statistics, the failure rate of piston pumps on the market is very high, and some of the products of well-known brands have failed. Therefore, the correct use of the piston pump is an important factor that directly affects its working life. If you want to make your pump last longer, please read the following content about the use and daily maintenance of the piston pump carefully.

First of all, the piston pump should be installed on a solid foundation frame or foundation without loosening. Before starting, check whether the following places are normal: the connection part is firm; the motor rotates in the correct direction; the clutch is flexible and reliable; the pipeline connection is firm, the sealing is reliable, the bottom valve is flexible and effective; the safety valve works reliably; the power end lubricating oil bit is normal. In addition, the suction pipe, bottom valve and pump body must be filled with water before starting, the upper end of the pressure gauge buffer should be filled with oil, and the piston should be allowed to reciprocate twice to ensure no-load start when there is no obstruction. After starting, wait for the machine to operate normally, and then slowly increase the load. During use, test the sand content of the mud from time to time. If the sand content of the mud exceeds 10%, stop immediately. If you buy a pump with multiple gears, try not to change gears during operation, stop the pump and then change gears. If there is abnormal noise or abnormal water volume and pressure during operation, or there is obvious high temperature, the pump should be stopped for inspection. Under normal circumstances, the pump should be stopped at no-load. When the pump is stopped for a long time, all the water holes should be opened, the cylinder head should be loosened, and the drain rod of the bottom valve should be lifted to discharge all the mud and sand in the pump body and pipeline. When using piston pump grouting, after the grouting is completed, the pump and the grouting pipeline should be cleaned with water using the quick stop.

Finally, what I want to say is that after purchasing the products of the Elephant brand, if you have any questions that you do not understand, you can ask our customer service staff in advance to prevent unnecessary losses due to improper operation. Finally, you are welcome to buy the hydraulic products of Elephant Fluid Power. If the big hydraulic piston pump you are using fails, we can also provide you with maintenance advice or help you repair it. If they have irreversible failures, You are welcome to buy the high-quality, low-cost big-name replacement products produced by Elephant!

piston pump troubleshooting

piston pump failure causes

piston pump diagram

hydraulic gear pump failure analysis

hydraulic pump failure modes

rexroth hydraulic pump troubleshooting

piston pump usage

piston pump parts and function

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu