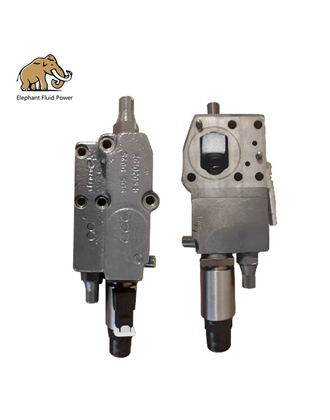

First, main parts of a hydraulic pump:

1.Casing: It is the outer shell of the hydraulic pump, which plays a role in protecting the internal components and fixing the structure. It is usually made of cast iron or aluminum alloy.

2. Pumping element: This is the core part of the hydraulic pump, including pistons, cylinders, and valve plates in piston pumps; gears in gear pumps; and vanes and rotors in vane pumps. These components work together to achieve the suction and discharge of hydraulic oil.

3. Drive shaft: It is used to connect the hydraulic pump to the power source, such as an engine or electric motor, and transmits the rotational power to the pumping element to make it work.

4. Bearings: They support the drive shaft and other rotating parts to ensure smooth rotation and reduce friction and wear. Common types include ball bearings and roller bearings.

5. Sealing elements: Such as oil seals and O - rings, which are used to prevent hydraulic oil from leaking out of the pump and ensure the normal operation of the hydraulic system.

6. Control mechanism: It includes components such as swash plates, control valves, and solenoids. The control mechanism is used to adjust the flow and pressure of the hydraulic pump according to the needs of the working conditions to achieve the control of the hydraulic system.

7. Suction and discharge ports: The suction port sucks hydraulic oil from the oil tank, and the discharge port discharges the pressurized hydraulic oil into the hydraulic system to supply power to the actuator.

Second, methods for maintaining hydraulic pump parts:

1.Regular oil change: Replace the hydraulic oil regularly according to the operating hours or time recommended by the manufacturer. The quality of the oil should meet the requirements of the pump. Clean oil helps to reduce wear on parts.

2. Filter maintenance: Regularly check and replace the oil filter. A clogged filter can cause poor oil flow and increased pressure, affecting the pump's performance.

3. Inspect for leaks: Routinely check the pump's casing, seals, and connection points for oil leaks. Replace damaged seals promptly to prevent oil leakage, which can lead to reduced efficiency and potential damage to other components.

4. Monitor operating parameters: Keep an eye on the pump's operating pressure, temperature, and flow rate. Abnormal values may indicate problems with the pump or its components.

5. Lubrication of moving parts: Some parts of the pump, such as bearings, need proper lubrication. Ensure that the lubricating oil level is sufficient and the lubricant quality is good.

6. Clean the exterior: Regularly clean the exterior of the pump to remove dirt, dust, and oil stains. This helps to dissipate heat and makes it easier to detect potential problems.

7. Handle with care during installation and removal: When installing or removing the pump, follow the correct procedures to avoid damaging the parts. Use appropriate tools and ensure proper alignment.

8. Store properly: If the pump needs to be stored for a long time, store it in a dry, clean place and protect it from dust, moisture, and corrosion.

Hydraulic hand pump parts

Hydraulic parts manufactures

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu