K3V hydraulic pump is a highly efficient, stable and durable hydraulic piston pump. The K3V hydraulic pump is a high-performance hydraulic piston pump manufactured by Kawasaki Heavy Industries. These pumps are highly regarded for their high efficiency, reliability and durability and are widely used in a variety of construction machinery and hydraulic systems.

First, structural features

1. Plunger design: K3V hydraulic pump adopts plunger design, which realizes the suction and discharge of liquid through the reciprocating motion of the plunger in the cylinder block. This design results in a pump with high pressure output capacity and good flow control.

2. Variable adjustment: This series of pumps has the function of variable adjustment, which can adjust the displacement of the pump according to the actual demand, so as to meet different working needs. This adjustment makes the pump more flexible and efficient in the application.

3. Compact structure: The K3V hydraulic pump has compact structure, small size, light weight, easy to install and maintain. At the same time, its design also takes into account the needs of heat dissipation and noise reduction, making the pump more stable and reliable during operation.

Second, performance parameters

The performance parameters of K3V hydraulic pump vary from model to model, but usually include the following aspects:

1. Displacement: Provide a variety of displacement options to meet the needs of different application scenarios. Users can choose the appropriate displacement according to actual needs to ensure the normal operation of the equipment.

2. Pressure: The working pressure range is wide, which can meet various working environments from low pressure to high pressure. This makes the K3V hydraulic pump more adaptable and stable in the application.

3. Speed: With a wide range of speed, users can adjust the speed according to the actual working conditions to achieve the best working efficiency.

4. Drive mode: usually driven by motor, but can also be driven by other ways such as hydraulic motor, pneumatic motor, etc.

Third, Applications

K3V hydraulic pumps are widely used in various construction machinery and hydraulic systems, such as:

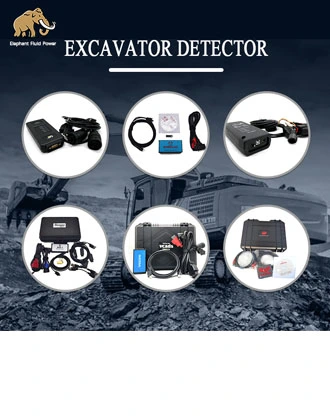

1. Excavator: K3V hydraulic pump is one of the main power sources of the excavator, providing stable hydraulic power for various actions of the excavator.

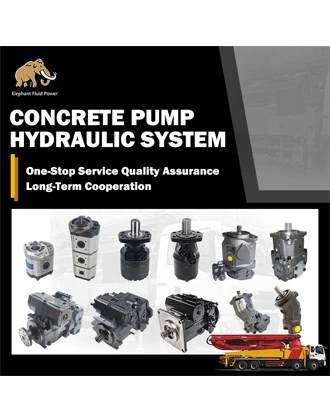

2. Concrete pump truck: In the concrete pump truck, the K3V hydraulic pump is used to drive the concrete pumping system to realize the conveying and pouring of concrete.

3. Crane: In the crane, the K3V hydraulic pump provides hydraulic power for the crane's lifting, slewing and luffing mechanisms.

4. Other construction machinery: such as loaders, road rollers, pavers, etc., K3V hydraulic pumps are also widely used in the hydraulic systems of these construction machinery.

Fourth, Maintenance & Maintenance

1. Check the fasteners: Check the fasteners of the product on a daily basis, such as screws, to ensure the stability of the pump body.

2. Clean the oil seal: Clean the oil seal frequently to prevent impurities and dirt from entering the pump body and affecting the service life of the pump.

3. Change the hydraulic oil: It is recommended to change the hydraulic oil after 500 hours of working for the first time, and then every 2000 hours or according to the oil quality. At the same time, replace the filter regularly to keep the hydraulic system clean.

4. Check the oil level and oil quality: Check whether the oil level of the hydraulic oil tank meets the requirements in daily use, and check whether the hydraulic oil contains water or has abnormal odor. If there is an abnormality, the hydraulic oil should be replaced immediately and the cause of the problem should be found.

Kawasaki K3V1 pump

K3V hydraulic pumps for sale

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu