The basic concept of the hydraulic system:

1. Hydraulic oil pressure:

The air we live in is at atmospheric pressure, and its value is about 1 bar. (1 bar = 0.1 MPa) atmospheric pressure retains the air on which we depend.

Submarines dive into the water, and they also bear the water pressure at the same time as the atmospheric pressure, so it is impossible to dive into the boat with unlimited depth.

In the hydraulic system, the hydraulic pressure causes the actuator to generate a corresponding force, thereby achieving the corresponding purpose. On the pump truck, in order to transport concrete from the ground to a certain height, a certain hydraulic oil pressure must be provided for the main cylinder on the pump truck.

Hydraulic oil flow:

In daily life, when we hit the water faucet at different angles, the amount of water flowing out in a certain period of time will be different, which means that the larger the angle, the greater the water flow.

In the hydraulic system, the flow of hydraulic oil determines the speed of the system. For example, on a pump truck, we increase the displacement to increase the number of hydraulic pump spare parts, so that the more concrete is pumped in a given time.

Hydraulic system power mechanism:

The power mechanism of the hydraulic system is what we usually call a "hydraulic pump", which generates hydraulic oil pressure and hydraulic oil flow for the hydraulic system to work.

Hydraulic system actuator:

Hydraulic system actuators include cylinders and motors. On the pump truck or tractor spare pump, we divide the cylinders into main cylinders, swing valve cylinders, boom cylinders and outrigger cylinders according to the purpose of each actuator. The motors are divided into stirring motors, air cooler motors, water pump motors and reducer motors.

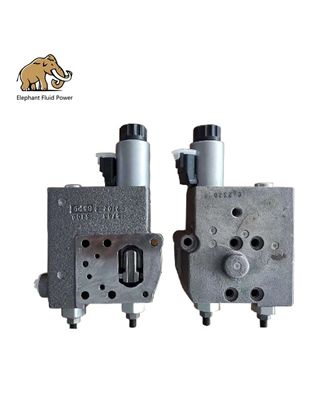

Hydraulic system control mechanism:

The hydraulic system control mechanism is mainly various control valves. On the pump truck, there are pressure control valves, directional control valves and flow control valves. Pressure control valves such as main relief valves, stacked relief valves, directional control valves such as main four-way valves, swing cylinder four-way valves, flow control valves such as boom multi-way valves.

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu