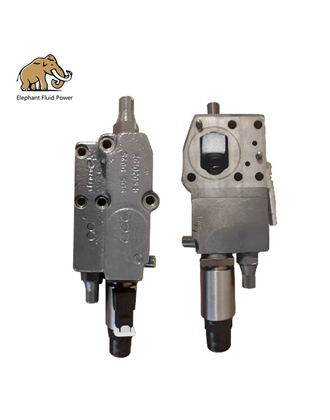

Directional valves are vital components within hydraulic systems, serving as the traffic controllers that dictate the flow of hydraulic fluid. These valves are integral to the control of hydraulic actuators like cylinders and motors. In this blog, we'll delve into the significance of directional valves within hydraulic systems, exploring their applications and various types.

The Significance of Directional Valves

Directional valves play a role analogous to traffic signals in a bustling city. They determine the route through which hydraulic fluid flows, dictating the movement of hydraulic actuators. These actuators are responsible for performing various tasks in hydraulic systems, such as lifting, pushing, pulling, or rotating. In the absence of directional valves, hydraulic systems would lack the ability to precisely control the motion of actuators. Whether in construction machinery, manufacturing processes, or even aerospace applications, directional valves ensure that hydraulic systems operate with accuracy and efficiency.

Applications of Directional Valves

Directional valves find extensive use in construction equipment like excavators, backhoes, and loaders. These valves control the hydraulic cylinders responsible for tasks such as extending or retracting the bucket arm, raising and lowering the loader, and tilting the blade. In industrial settings, directional valves are integral to automated manufacturing processes. They regulate the movement of hydraulic actuators in machines responsible for assembling, shaping, or packaging products on production lines. In the aerospace industry, hydraulic systems rely heavily on directional valves to control critical components such as landing gear, wing flaps, and aircraft doors. The precise operation of these valves is paramount for ensuring safe and controlled flight operations.

Types of Directional Valves

Directional valves come in various types, each designed to suit specific applications and operational requirements. Spool valves are among the most common directional valves. They use a spool, a cylindrical component, to control the flow of hydraulic fluid. Depending on the valve's configuration, they can offer 2-way, 3-way, or 4-way flow paths. These valves are versatile and widely used in various industries. Poppet valves utilize spring-loaded discs (poppets) to regulate flow. They are known for their fast response times, making them suitable for applications that require quick changes in flow direction. Poppet valves are often used in high-pressure systems. Rotary valves utilize rotating mechanisms to control fluid flow. They are well-suited for applications requiring high flow rates and are often employed in scenarios where flow needs to be controlled precisely and consistently.

In conclusion, directional valves are the keystones of hydraulic systems, enabling controlled movement and operation of hydraulic actuators. Their applications range from construction machinery to aerospace, and their types vary to suit specific needs. By understanding their significance and functionality, we gain insights into the essential role directional valves play within hydraulic systems.

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu