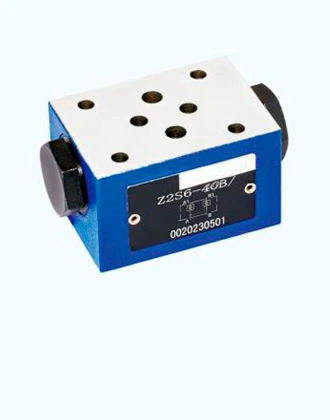

Introduction to directional control valve

Manual directional valve has two or more flow modes and more than two oil ports. It is a valve that implements hydraulic oil flow interconnection, cut-off and reversal, as well as pressure unloading and sequential action control. It can be divided into manual directional valve, electromagnetic change-over valve, electric-hydraulic change-over valve, etc. Also known as Chris valve, it has multi-directional adjustable channels and can timely change the direction of fluid flow. This manual directional valve has a wide range of applications in petroleum and chemical production, and is more commonly used in synthetic ammonia production systems. In addition, the change-over valve can also be made into a valve flap structure, mainly used for low flow occasions.

Characteristics of directional control valve

Manual directional valve has ultra-high pressure, small size, light weight, and compact structure. It is easy to operate and has strong versatility. The change-over valve (also known as a three-way gate valve) can be made of stainless steel or carbon steel and the transmission mode can be manual, pneumatic, or electric. The change-over valve can be used under normal pressure and also under pressure less than 0.1Mpa. It is used in the process of free-fall of bulk solid materials, switching from the main conveying pipe to the branch pipe, and is installed under the hopper in the case of gravity feed. It is usually used for bulk powders and granular materials and can also be installed on the chute.

Directional control valve uses precision processed sealing structure to effectively prevent material leakage to the closed side. The sealing elements of the change-over valve are very tight and it is almost impossible for internal leakage to occur. It can be used in chemical, food, power, and construction materials, etc. It is widely used in industry. We design and manufacture different types of change-over valves for users based on the material characteristics of different industries. There are four control modes for change-over valves, namely handwheel, chain wheel, motor resistance, and cylinder. The flange shape is circular or square.

The change-over valve, also known as the diverter valve or switch valve, is used in the powder material dilute phase pneumatic conveying systems (air conveying systems) of the chemical, food, and grain industries. It mainly transports ABS plastic particles, grains, flour, and private chat and other materials that have low abrasion and low hardness. During transportation, the deviation of the valve core is used to switch the material so that the material flows into the designated storage area or enters the tanker. The manual directional valve is used in pressure conveying occasions, with a pressure less than 0.1Mpa, and is generally installed on the air conveying pipeline.

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu