First, Core Parameters and Characteristics of the A10VSO 100 Pump

The A10VSO 100 pump is a swashplate-type axial piston variable displacement pump from the Rexroth brand, specifically designed for open hydraulic circuits. It features the following core parameters and characteristics:

1. Displacement and Flow Rate:

The displacement specification is 100 cm³/rev. Flow rate is proportional to both drive speed and displacement, enabling stepless variable control by adjusting the swashplate angle.

At the rated speed of 2000 rpm, the maximum flow rate reaches 200 L/min, meeting high-flow application requirements.

2. Pressure Capability:

Rated pressure is 280 bar, with a peak pressure of 350 bar, suitable for high-pressure hydraulic systems.

Equipped with a constant pressure control valve (e.g., DR valve), providing approximately 50 bar per revolution of adjustment for precise system pressure setting.

3. Control Modes:

Supports multiple control modes including Pressure Control (DR), Remote Pressure Control (DRG), and Pressure-Flow Composite Control (DFR) to meet diverse operational requirements.

Load-sensing control (e.g., DFR1) automatically adapts to load variations, optimizing system efficiency.

4. Structure and Installation:

Features a through-shaft design for easy multi-pump integration, suitable for complex hydraulic systems.

Mounting flanges comply with ISO or SAE standards, facilitating seamless integration into existing systems.

5. Performance Advantages:

Low-noise design ensures smooth operation, enhancing workplace comfort.

Long-life design with precision-matched critical components (e.g., cylinder blocks and distribution plates) minimizes leakage and extends service life.

Drive shafts withstand axial and radial loads, accommodating diverse mounting configurations.

Second, Typical Application Scenarios for the A10VSO 100 Pump

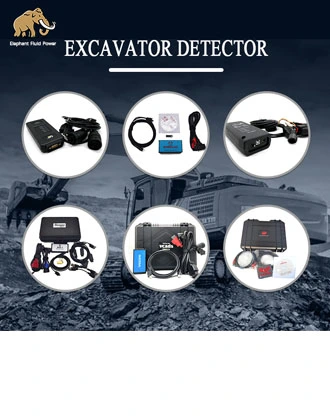

1. Construction Machinery:

Power hydraulic systems in excavators, loaders, and similar equipment, delivering high-pressure, high-flow hydraulic power to execute complex movements.

Load-sensing control optimizes system efficiency and reduces energy consumption.

2. Industrial Equipment:

Suitable for injection molding machines, die-casting machines, and other industrial equipment requiring precise pressure control to ensure stable product quality.

Pressure-flow composite control meets equipment demands across varying operating conditions.

3. Metallurgical Machinery:

Used in rolling mills, continuous casting machines, and other metallurgical equipment, providing stable high-pressure hydraulic power to support continuous operation.

Long-life design minimizes equipment downtime and enhances production efficiency.

4. Marine and Offshore Engineering:

Suitable for hydraulic systems in ship steering gears, deck machinery, and similar applications, withstanding harsh marine environments.

Through-shaft design facilitates multi-pump configurations to meet complex marine hydraulic system requirements.

A10VSO 28 pump

Rexroth A10VSO 14

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu