If you're using a hydraulic pump such as the A10VSO, you may need to adjust the pressure at some point. Pressure adjustment is important because it determines the force with which your hydraulic system operates. In this article, we'll discuss how to adjust the pressure of your A10VSO hydraulic pump.

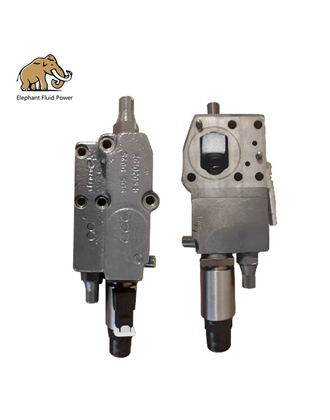

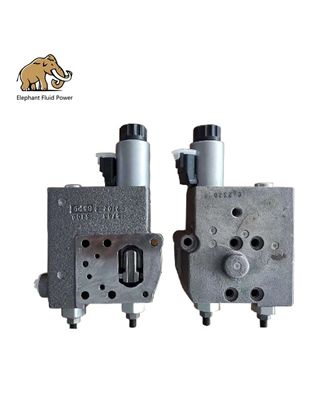

Step 1: Identify the Pressure Adjustment Screw

The pressure adjustment screw is typically located on the top of the pump. It's a small screw with a locknut that holds it in place. To access it, you may need to remove a cover or a protective cap. Thus, It is essential to have access to reliable hydraulic pump spare parts and skilled professionals to ensure proper maintenance and swift replacement of crucial components like the pressure adjustment screw.

Step 2: Determine the Current Pressure

Before you make any adjustments, you need to determine the current pressure of your hydraulic system. You can use a pressure gauge for this purpose. Attach the gauge to the pressure port on the pump and read the pressure.

Step 3: Adjust the Pressure

To adjust the pressure, turn the adjustment screw clockwise to increase the pressure and counterclockwise to decrease it. Make small adjustments at a time and check the pressure using the gauge after each adjustment. You may need to make several adjustments before you achieve the desired pressure. With a constant pressure hydraulic pump, it may take several adjustments before arriving at the desired hydraulic pressure, so patience and diligence are key.

Step 4: Lock the Adjustment Screw

Once you've achieved the desired pressure, lock the adjustment screw in place using the locknut. This will prevent the screw from moving and changing the pressure accidentally.

Step 5: Test the System

After you've made the adjustments and locked the screw, test the hydraulic system to ensure it's operating correctly. Check for leaks, unusual noises, or other signs of malfunction. If everything is working correctly, you're done.

In conclusion, adjusting the pressure of your A10VSO hydraulic pump is a straightforward process that anyone can do. However, it's important to be careful and make small adjustments at a time to avoid damaging the system. By following the steps outlined in this article, you can adjust the pressure of your hydraulic system and ensure it operates at the desired level.

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu