First, Components

1. Pump Body

The pump body is the basic structure of A20VLO pump, usually made of cast iron or other materials, which provides space and support for the other parts of the pump, and protects the internal parts from the external environment.

2. Plunger and Cylinder

Plunger: It is the key component to realize the function of oil suction and oil pressure. In the working process of the pump, the plunger makes reciprocating linear movement in the bore of the cylinder body, and completes the oil suction and discharge process by changing the volume of the sealed working chamber.

Cylinder: The cylinder is distributed with several holes for installing the plunger, and the cylinder rotates with the drive shaft to drive the plunger to do reciprocating motion.

3. Distributor plate

The distributor plate is closely fitted with the cylinder body and plays a role in distributing the oil. In the process of cylinder rotation, the flow distribution disk makes the plunger working chamber connect with the suction port and discharge port alternately to ensure that the pump can continuously suction and pressure oil.

4. Swash plate

Swash plate is an important part of the variable mechanism, its inclination can be adjusted. By changing the inclination of the swashplate, the plunger can be changed in the cylinder stroke, thus realizing the adjustment of the pump displacement. When the inclination of the swashplate increases, the plunger stroke increases and the displacement of the pump increases; conversely, the displacement decreases.

5. Drive shaft

The drive shaft transmits the power from the engine or motor to the cylinder, which rotates the cylinder and drives the plunger to move, thus converting the mechanical energy into hydraulic energy.

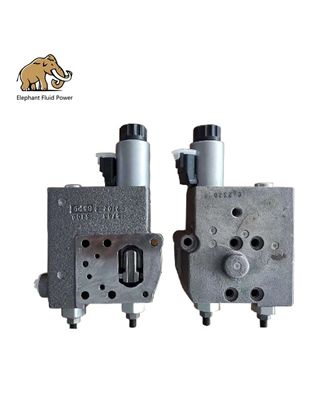

6. Variable Mechanism

The variable mechanism is used to control the inclination of the swash plate to adjust the displacement of the pump. It can automatically or manually change the angle of the swash plate according to the demand of the system, to realize the pump flow adjustment, to meet the requirements of different working conditions.

Second, the basic working principle

A20VLO pumps use the plunger to reciprocate in the cylinder, so that the volume of the sealed working chamber changes to realize oil suction and pressure. When the plunger extends outward, the volume of the sealed working chamber increases gradually, forming a local vacuum, and the oil in the tank enters the working chamber through the suction valve under the action of atmospheric pressure to complete the suction process; when the plunger retracts inward, the volume of the sealed working chamber decreases gradually, and the oil is squeezed, the pressure rises, and the oil is discharged into the system through the pressure valve to realize the oil pressure process.

Variable adjustment principle: The pump is equipped with variable mechanism to change the displacement by adjusting the inclination angle of the swash plate, supporting stepless flow adjustment. When the swashplate tilt angle increases, the plunger stroke in the cylinder increases, the volume change of the sealed working chamber increases, and the displacement of the pump increases; on the contrary, when the swashplate tilt angle decreases, the plunger stroke decreases, and the displacement of the pump decreases. Part of the model adopts constant flow swashplate design, which can automatically adjust the swashplate inclination and change the displacement when the load changes to maintain a constant flow rate of the system.

Technology Combination Principle: Through the combination of microelectronic technology and hydraulic system, the transmission strength and precision can be improved. Microelectronic technology can accurately control the variable mechanism to adjust the swashplate inclination angle, so that the pump can accurately adjust the displacement and output pressure according to the actual demand of the system, to better meet the performance requirements of the hydraulic system in industrial automation, mobile machinery and renewable energy and other fields.

Rexroth A20VLO hydraulic pump

Rexroth A20VLO Series Pumps

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu