A2FM motor refers to the A2FM - series axial - piston fixed - displacement hydraulic motor, which is widely used in the field of hydraulic transmission.

First, detailed introduction of A2FM motor:

1.Structural features: It is equipped with an axial tapered piston rotor group with a bent - axis design. This structure enables it to have good performance in both open - circuit and closed - circuit hydrostatic drives.

2. Working principle: The output speed is determined by the flow of the pump and the displacement of the motor, which is proportional to the input flow and inversely proportional to the displacement. The output torque increases with the increase of the pressure difference between the high - pressure side and the low - pressure side and the displacement.

Inlet of high - pressure oil

High - pressure hydraulic oil enters the motor through the inlet port. The oil then flows into the piston chambers of the motor.

Piston movement

The pressure of the high - pressure oil acts on the pistons, causing them to be pushed outwards. In the A2FM motor, the pistons are arranged in an axial - piston configuration. As the pistons are pushed by the oil pressure, they move within their respective cylinders.

Rotation of the rotor

The movement of the pistons causes the rotor to rotate. The pistons are connected to the rotor in a way that their reciprocating motion is converted into rotational motion of the rotor. As the high - pressure oil continues to act on the pistons, the rotor rotates continuously.

Outlet of low - pressure oil

After the oil has done work on the pistons and the rotor, it becomes low - pressure oil. This low - pressure oil is then discharged from the motor through the outlet port and returns to the hydraulic system's oil tank or other components for recirculation.

The speed of the A2FM motor's rotation is determined by the flow rate of the incoming high - pressure oil, while the output torque is related to the pressure difference between the inlet and outlet of the motor and the displacement of the motor.

3. Main specifications: There are various specifications, and the displacement ranges from 5 cm³/rev to 1000 cm³/rev. The nominal pressure can reach up to 400 bar, and the maximum pressure can reach 450 bar. The maximum speed can reach 11000 rpm in some specifications.

4. Product characteristics: It has the advantages of high power density, small size, high overall efficiency, and good starting characteristics. At the same time, it adopts a standard interface design, which is easy to install, and can be combined with other standard hydraulic components.

5. Application scenarios: It is suitable for mobile and stationary applications, and is widely used in construction machinery, engineering machinery, lifting machinery, metallurgical machinery and other fields, such as excavators, concrete mixer trucks, cranes, etc.

Price of A2FM motor

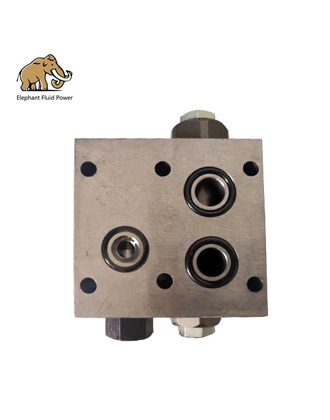

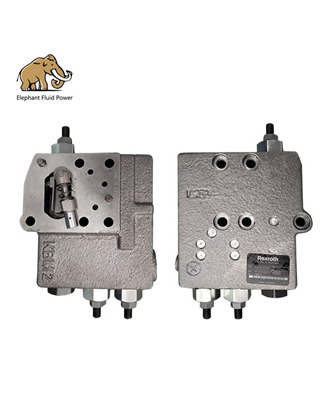

A2FM motor parts

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu