A2FM motor is a type of hydraulic motor.

Features:

1. High power density: It can provide a relatively large output torque in a small size, making it suitable for applications where space is limited.

2. Reliable performance: Known for its durability and stability, it can operate under various working conditions.

3. Variable displacement option: Some models of A2FM motors offer variable displacement, allowing for flexible control of speed and torque.

Applications:

1. Construction machinery: Such as excavators, loaders, and cranes, where it is used to drive various hydraulic actuators.

2. Industrial equipment: In manufacturing processes that require precise control of movement and high torque output.

3. Mobile machinery: Like agricultural machinery and mining equipment.

Here are some ways to maintain the A2FM motor:

Regular Inspection

1. Check for leaks: Inspect the motor regularly for any signs of hydraulic fluid leakage. Leaks can lead to reduced performance and potential damage to other components. If a leak is detected, identify the source and repair it promptly.

2. Examine connections: Ensure that all hydraulic connections are tight and secure. Loose connections can cause pressure losses and potential failures.

3. Look for physical damage: Check the motor housing for cracks, dents, or other physical damage. Any damage should be addressed immediately to prevent further deterioration.

Hydraulic Fluid Management

1. Use proper fluid: Always use the recommended hydraulic fluid for the A2FM motor. Using the wrong fluid can cause poor performance, increased wear, and potential damage.

2. Monitor fluid quality: Regularly check the hydraulic fluid for contamination, such as water, dirt, or metal particles. Contaminated fluid can damage the motor's internal components. Change the fluid and filter as per the manufacturer's recommendations.

3. Maintain proper fluid level: Ensure that the hydraulic fluid level is within the specified range. Low fluid levels can cause cavitation and damage to the motor.

Operating Conditions

1. Avoid overloading: Do not operate the motor beyond its rated capacity. Overloading can lead to excessive wear and premature failure.

2. Control operating temperature: Keep the motor within its recommended operating temperature range. High temperatures can degrade the hydraulic fluid and damage the motor's internal components. Provide adequate cooling if necessary.

3. Follow proper startup and shutdown procedures: Follow the manufacturer's guidelines for starting and shutting down the motor to minimize stress on the components.

Periodic Maintenance

1. Clean the motor: Periodically clean the motor housing and external components to remove dirt and debris. Use a mild detergent and a soft cloth or brush.

2. Lubricate moving parts: Some A2FM motors may have lubrication points for certain moving parts. Follow the manufacturer's instructions for lubrication intervals and use the appropriate lubricant.

3. Inspect and replace wear parts: Over time, wear parts such as seals, bearings, and brushes may need to be replaced. Monitor the motor's performance and replace worn parts as needed to maintain optimal operation.

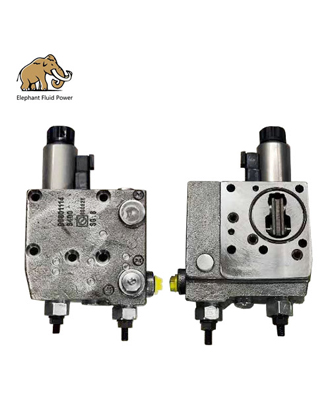

Bosch rexroth A2FM

Rexroth A2FM specs

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu