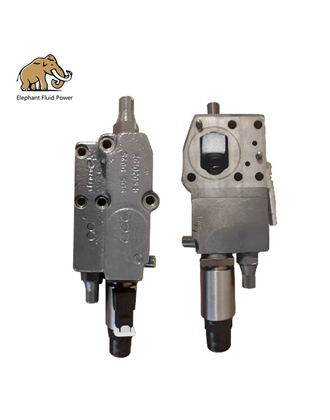

A10VSO is a swashplate-type axial piston variable displacement pump for open-circuit hydraulic systems, renowned for high power density, precise control, and reliability—ideal for mobile and industrial applications.

First, Core Specifications

1.Series & Displacement: 31 series (18/28/45/71/100/140 cm³/r); 32 series (45–180 cm³/r)

2.Pressure Ratings: Rated 280 bar; Peak 350 bar

3.Key Features: ISO standard mounting flange, through-drive capability, dual case drain ports, radial/axial load-bearing drive shaft

Second, Core Structure & Working Principle of Axial piston variable pump a10vso

1. Rotating Group: Drive shaft → cylinder block → plunger-slipper assemblies. Slippers ride on the swashplate via spherical joints; spring retainer plate keeps slippers sealed against the swashplate.

2. Swashplate & Servo Mechanism: Inclined swashplate forces plunger reciprocation. Servo cylinder/control valve adjusts swashplate angle via pilot pressure—angle↑=stroke↑=flow↑; angle 0=zero output.

3. Valve Plate: Distributes suction/discharge oil; precision-machined with wear-resistant coating to minimize internal leakage.

4. Regulator Block: Integrates pressure/flow/power control valves; pilot pressure signals trigger swashplate angle adjustment for load-sensing control.

5. Housing & Seals: Cast iron housing for rigidity/vibration damping; shaft lip seals, O-rings, gaskets prevent internal/external leakage.

Third, Key Performance Advantages

1.Excellent suction performance, anti-cavitation; low pressure pulsation and noise.

2.Fast response, high control accuracy, suitable for closed-loop and compound control.

3. High power density, long service life, extended maintenance intervals.

4. Versatile control options and through-drive for flexible system integration.

Fourth, Typical Applications

1.Mobile Hydraulics: Excavators, loaders, cranes, concrete pumps.

2.Industrial Hydraulics: Injection molding machines, die-casting machines, rolling mills, presses.

Fifth, Critical Maintenance & Operation Tips

1.Fluid Quality: Use clean hydraulic oil (NAS 8 class or better); replace oil and high-precision filters regularly.

2.Temperature Control: Maintain oil temperature at 30–55°C; avoid long-term operation above 60°C.

3.Installation & Commissioning: Ensure drive shaft alignment, torque specifications, and pilot pressure matching. Calibrate control parameters per manual.

4.Failure Prevention: Monitor pressure, temperature, noise, and leakage. Common issues: internal leakage (worn valve plate/slippers), swashplate sticking (contamination), bearing damage (insufficient lubrication).

Elephant Fluid Power Technical team has Worry-free delivery time 1300 kinds in stock, One-stop service, directly with the manufacturer, Provide complete hydraulic system solutions, Please contact us to purchase our products.

Bosch axial piston pump specifications

Bosch axial piston pump

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu