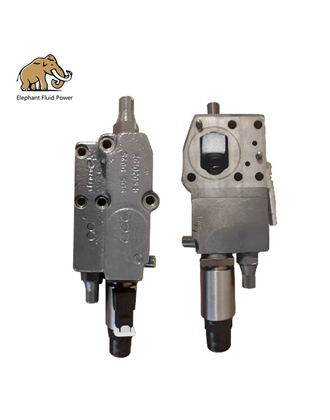

The hydraulic pump is the power component of the hydraulic system, which is driven by the engine or motor, sucks oil from the hydraulic oil tank, forms a pressure oil discharge, and sends it to the actuator. There are many types of hydraulic pumps, among which the elephant hydraulic products M46 series is designed for medium power applications with a maximum load pressure of 345 bar (5000 psi). This series can be combined with other products to form a system to transfer and control hydraulic energy. The M46 series is capable of continuously variable speed from zero to maximum speed in both forward and reverse operation modes. The M46 pump is a compact high power density element. All models use a parallel axial plunger/slipper design concept combined with a tilting swash plate to vary pump displacement. The M46 system may contain an integrated fuel pump to supply the system with hydraulic, cooling, and servo control fluids. The M46 pump is available with a series of auxiliary mounting measures for attaching auxiliary hydraulic pumps.

The M46 pump is available in manual, hydraulic or electrical drive mode with proportional control. Electrically controlled three position control is also available.

The pump receives fluid directly from the reservoir through the inlet line. A screen placed in the inlet protects the pump from large contaminants. The output of the pump is directed to a PVG-32 multi-section load sensing directional control valve which directs fluid to the actuators in the system. Fluid returning from the system is cooled by a heat exchanger and cleaned by a filter before returning to the reservoir. The speed of the actuators in the system depends on the volume of fluid being provided by the pump. The operating pressure varies depending on actuator load, but is limited to an adjustable maximum setting by the PC section of the pump control and by a system relief valve integrated into the side module of the PVG valve. The position of the PVG valve sets the demand for flow in the system and communicates this to the pump control by means of a hydraulic signal (load sense signal). The pump will provide as much flow to the system as it demands Therefore flow and pressure in the system are compensated to meet requirements.

If you have a need about Danfoss M46 pump parts, feel free to contact us! We provide original replacements of this series. Also, you can get a top quality with a good price. Our products have been exported to Germany, Norway, Poland, Finland, Spain, UK, France, Russia, USA, Brazil, Mexico, Australia, Japan, Korea, Thailand, Indonesia and many other countries.

danfoss m46 motor service manual

sauer-danfoss m46 major repair manual

sauer danfoss m46 tandem pump parts manual

danfoss mpv046 technical manual

danfoss series 42 parts manual

danfoss mpt044

danfoss m46 3013

m46 20875

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu