Excavator main pump refers to the main hydraulic pump of an excavator. It is a crucial component of the excavator's hydraulic system, which converts the mechanical energy of the engine into hydraulic energy. The following is a detailed introduction:

First, Function:

The main pump draws hydraulic oil from the hydraulic oil tank and delivers it as pressure oil to various hydraulic actuators of the excavator, such as the boom cylinder, arm cylinder, bucket cylinder, and swing motor, to provide power for the movement of the working device.

Second, Working Principle:

1. Piston pump principle

Suction stroke: As the piston moves downward in the cylinder, the volume of the working chamber increases, creating a vacuum. This causes hydraulic oil to be sucked into the working chamber through the suction valve from the hydraulic oil tank.

Discharge stroke: When the piston moves upward, the volume of the working chamber decreases, which increases the pressure of the hydraulic oil. The high - pressure oil is then forced out of the working chamber through the discharge valve and into the hydraulic system's pipeline to supply power to various components.

2. Control mechanism

Flow control: The excavator's main pump is usually a variable - displacement pump. The swash plate or wobble plate inside the pump can change the angle. A larger angle means a larger displacement per rotation of the pump, increasing the flow of hydraulic oil. When the operator moves the control lever, the control system adjusts the angle of the swash plate or wobble plate according to the movement of the lever, thereby changing the output flow of the pump to meet the requirements of different working speeds.

Pressure control: The main pump also has a pressure - limiting mechanism. When the pressure in the hydraulic system exceeds the set value, the pressure - limiting valve opens, and part of the hydraulic oil returns to the oil tank, which limits the maximum pressure of the system to protect the components of the hydraulic system from being damaged by excessive pressure. In addition, through the load - sensing system, the pump can automatically adjust the output pressure according to the load of the actuator, so that the system can work efficiently under different load conditions.

Third, Common Types:

There are mainly gear pumps, piston pumps, and vane pumps. Gear pumps are simple in structure and low - cost, but have lower pressure and flow accuracy. Piston pumps can achieve high - pressure and large - flow output, with high efficiency and good control performance, and are widely used in medium and large - sized excavators. Vane pumps have stable operation and low noise, but are less adaptable to high - pressure environments.

Fourth, Maintenance Considerations: Regular maintenance is required to ensure its optimal performance. It is necessary to prevent the entry of impurities to avoid wear and blockage of components, check for oil leakage, and monitor the oil temperature to prevent overheating. In addition, regular replacement of hydraulic oil and oil filters is also an important measure to ensure the normal operation of the excavator main pump.

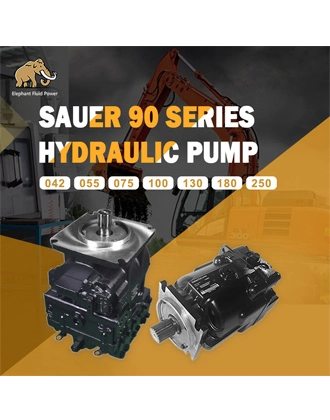

Used hydraulic pumps for excavators

Excavator hydraulic pump

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu