Factors affecting the service life of hydram pump

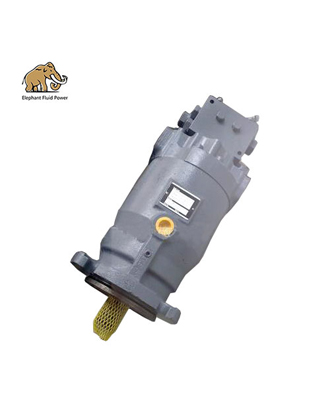

A hydram pump is a power component of a hydraulic system and is driven by an engine or a motor to absorb oil from the hydraulic oil tank, generate pressure oil discharge, and deliver it to the execution component. The hydram pump can be classified into gear pump, plunger pump, vane pump, and screw pump according to its structure. It is a hydraulic component that provides pressurized fluid for hydraulic transmission, which can convert the mechanical energy of the power machine (such as the electric motor and the internal combustion engine) into the pressure energy of the fluid. The working principle of the hydram pump is to change the pump chamber volume due to the movement, thereby compressing the fluid to provide pressure energy. The necessary condition is that the pump chamber has a sealable volume change.

There are many factors affecting the service life of a hydram pump. In addition to the design and manufacturing factors of the pump itself, the selection of related components (such as couplings, oil filters, etc.) and the operation during the trial run process are also related. So, will the misalignment of the shaft affect the service life of the hydram pump and hydro bearings?

Shaft misalignment causes damage to hydro bearings

All types of hydram pumps use hydro bearings to support the shaft. If the shaft is misaligned, it will also cause damage to the bearing. The improper alignment between the critical moving parts inside the hydram pump will affect the performance and the bearing life of the pump. When the internal working of the pump is normal, there will be a small gap between the hydro bearings and other moving parts. When the misalignment occurs, the gap will no longer be uniform, and the moving parts will now come into contact with each other. Gradually, the moving parts will generate friction and wear on each other. Friction will produce additional heat and cause overheating issues. In addition, small metal shavings may enter the hydraulic oil and contaminate the hydraulic oil. These shavings may jam in hoses, valves, and other such locations within the hydraulic system. As a result, the overall efficiency of the pump decreases. As you can probably guess, the excessive wear of the pump bearing leads to its eventual failure due to improper operation.

It can be seen that when the hydro bearings are misaligned, they will shorten the life of the pump. However, you can take some measures to help prevent misalignment issues. Some special tools are used in predictive maintenance plans to check for vibration, heat, and other such measures to confirm the possibility of misalignment. By using these tools as a part of your predictive maintenance plan, you can better identify and correct misalignment when it occurs. By resolving misalignment issues early, you will ensure that your hydram pump achieves maximum service life.

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu