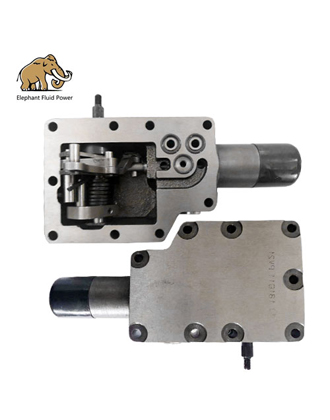

Kawasaki K3V112DT hydraulic pump is a popular product currently sold by Elephant Fluid Power. The hydraulic pump produced by Elephant Fluid Power is not only of good quality, cost-effective and has a long service life, but even the best product must follow certain methods in the use process, otherwise it will damage the product and affect the use of the product. In order to facilitate the use of customers, Elephant Fluid Power will share with you how to use the k3v112dt kawasaki pump parts, and I hope you will strictly abide by it.

1. Prevent the mixing of pollutants and water

(1) Strengthen the management of safety and cleaning work such as oil depots, oil drums, oil filters, oil funnels and oil pipes, so that they are specially used, kept clean before and after use, and no pollutants are mixed in.

(2) When the simple method is used to identify the degree of pollution on site, the hydraulic oil must be replaced in the following situations:

a. THE SIZE OF THE PARTICULATE MATTER IS GREATER THAN 40UM, THAT IS, WHEN IT IS VISUALLY VISIBLE OR WHEN THE USED OIL IN THE TEST TUBE IS BLACK AND HAS A FOUL ODOR;

b. When the heated oil droplets have residual black spots on the filter paper; 3. When a drop of used oil is dropped on an iron plate heated to 250 degrees Celsius and there is an explosion sound (containing moisture).

c. There is often water at the bottom of the oil barrel, and the air in the system contains water vapor and will condense into water, which should be eliminated.

2. Prevent air from entering

(1) Keep enough oil (height) in the tank, and keep the oil suction pipe port and the oil return pipe port below the oil level.

(2) Use seals with good performance, and tighten the screws of the pipe joints and each joint surface.

(3) Prevent the pressure everywhere in the system from falling below atmospheric pressure or local vacuum.

(4) Open the cylinder exhaust valve before starting the machine or when replacing the new oil, and move back and forth several times within the maximum stroke range of the cylinder to exclude air.

3. Prevent system leakage

The leakage of the hydraulic system can be divided into external leakage and internal leakage. External leakage is mainly to the outside, such as pipe leakage and cylinder leakage. If the internal leakage is the leakage from the high-pressure cavity to the low-pressure cavity inside the component, it directly affects the performance of the component.

(1) The quality of the weldments of the casting should be guaranteed, and when conditions permit, the hydraulic parts should be subjected to pressure test before assembly, and the pressure of the pressure test should reach 150%-200% of the maximum working pressure.

(2) When installing various joints, be sure to make the fastening nut fit properly with the thread on the joint. Especially when installing for the first time, the burrs should be removed, otherwise, the hard tightening with burrs will squeeze the thread and leave future trouble. When assembling the joint, you can first tighten the cover contact with your hand, when the hand cannot be screwed. Indicates that the sealing surface has been touched and then tightened with a wrench.

(4) Ensure the quality of oil seals and seals, and the material, geometry and precision should meet the design requirements.

Oil contamination is the main cause of hydraulic system failure and premature wear or damage to hydraulic components. Reasonable selection of hydraulic oil, correct maintenance of hydraulic system, according to the actual situation, for unreasonable places to make appropriate adjustments, effectively avoid hydraulic system failure. It not only leaves considerable maintenance costs for the enterprise, but also improves production efficiency.

During the use process, if you need technical support, you can also contact Elephant Fluid Power, Elephant Fluid Power promises that all products sold have a warranty period of up to one year, during which you can contact the company if there is any problem with the product, our commitment is true and effective, and will never deceive consumers.

Kawasaki K3V112DT Hydraulic Pump

kawasaki k3vl 140 pump

kawasaki k3vl80

kawasaki hydraulic pump usa

k3vl80

kawasaki hydraulic pump distributors

kawasaki pump parts

kpm pump

k3vls65

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu