As the core power component of hydraulic systems, hydraulic pumps feature complex and precision-engineered components. The following provides a detailed introduction across three aspects: core components, auxiliary components, and specialized components unique to different pump types:

First, Core parts of hydraulic pump

1. Pump Housing: Serving as the hydraulic pump's outer structure, the housing encloses the pump's rotating components, providing containment and support. It protects internal parts from external environmental damage and ensures stable pump operation.

2. Rotor: The primary moving element within the hydraulic pump, responsible for converting mechanical energy into fluid pressure energy. The rotor's motion pattern is closely tied to the pump type, such as gears in gear pumps, vane rotors in vane pumps, or pistons in piston pumps.

3. Shaft: Connects the motor to the pump body, transmitting mechanical power. Typically crafted from high-strength materials, the shaft withstands rotational torque and pressure, ensuring efficient and stable pump operation.

4. Sealing Devices: Prevent fluid leakage and maintain system pressure. Common sealing materials like rubber and nylon effectively contain hydraulic fluid, guaranteeing system functionality.

Second, Auxiliary parts of hydraulic pump

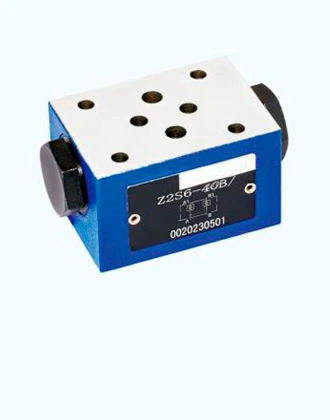

1. Inlet/Outlet Valves: Regulate fluid flow to ensure proper hydraulic system operation. These valves precisely regulate fluid flow rate and direction according to system requirements, enabling accurate control of hydraulic actuators.

2. Oil Seals and Gaskets: Similar to sealing devices but primarily focused on preventing hydraulic fluid leakage from the pump housing to the external environment. They are typically installed at critical pump locations such as shaft ends and pump covers to ensure sealing integrity.

3. Inlet/Outlet Connectors: Interfaces linking the hydraulic pump to the reservoir or other hydraulic components. They ensure smooth oil flow within the system and prevent leakage at connection points.

4. Pressure Valves and Relief Valves: Regulate system pressure to protect against overpressure. When pressure exceeds set limits, these valves automatically open to release excess fluid, safeguarding the system from damage.

5. Thermometers and Pressure Gauges: Monitor the temperature and pressure within the hydraulic system. They provide real-time display of the system's operating status, helping operators promptly identify and address potential issues.

6. Hydraulic Hoses and Accessories: Connect various hydraulic components and transport fluid. The quality of hoses and accessories directly impacts the stability and reliability of the hydraulic system. Therefore, it is essential to select hoses and accessories that are reliable, corrosion-resistant, and capable of withstanding high pressure.

Third, Distinct parts of Different Hydraulic Pump Types

1. Gear Pump:

Gears: The core components responsible for fluid conveyance and pressure amplification. Parameters such as tooth profile, number of teeth, and module directly influence gear pump performance.

Side Plates: Protect internal pump components while enhancing structural strength and rigidity. These plates typically fit tightly with the pump body to ensure stable gear pump operation.

2. Vane Pumps:

Vane: The key component of a vane pump, responsible for creating volumetric changes during rotor rotation to achieve fluid delivery. Parameters such as the vane's material, shape, and quantity directly affect the pump's performance.

Stator: Works in conjunction with the vane to form a sealed space for volumetric changes. The shape and dimensions of the stator's inner surface significantly impact the vane pump's performance.

3. Plunger Pump:

Plunger: The core component of the plunger pump, responsible for reciprocating motion within the pump cylinder to achieve liquid delivery. Parameters such as the plunger's material, diameter, and stroke directly affect the pump's performance.

Swashplate: Works in conjunction with the plunger. By altering the swashplate's angle, the flow rate of the plunger pump is regulated. The design and adjustment of the swashplate are crucial for performance control.

Hydraulic pump parts list

Hydraulic pump replacement parts

Mechanical hydraulic pump parts

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu