Hydraulic pump is a hydraulic component composed of multiple moving parts with complex structure. Kawasaki k3v112dt hydraulic pump After working for a period of time, its parts are prone to wear and damage, resulting in increased oil leakage, reduced system flow, reduced system pressure, and decreased volumetric efficiency. Practice has proved that timely fault diagnosis of hydraulic pumps, identification of fault causes, troubleshooting of faults, and timely maintenance inspection of hydraulic pumps as required can effectively ensure the normal operation of hydraulic pumps and extend the service life of hydraulic pumps. kawasaki k3v112dt hydraulic pump common faults are mainly as follows:

1. The work efficiency of the hydraulic pump is not high

In hydraulic equipment, the hydraulic pump is regarded as the heart of the hydraulic equipment, and the hydraulic oil is the "blood" in the system. With the development of hydraulic pump to high pressure, large flow, low noise, long life, whether the choice of hydraulic pump oil is reasonable, directly related to the performance and efficiency of the equipment, related to the service life and maintenance costs of the hydraulic pump. At the same time, it can also extend the oil change cycle of the oil itself, saving purchase funds.

2. The moving element of the hydraulic pump fails, and the hydraulic oil is oxidized and deteriorated

The main cause of hydraulic pump failure and component failure is that the hydraulic oil contains superscalar contaminants. Because the sources of pollutants in the oil are different, the shape is different, and the cleanliness of the oil directly affects the working condition and parts life of the hydraulic pump, so it is very important to control the oil pollution of the hydraulic piston pump spare parts.

3. Leakage problem

Hydraulic pump in the normal operation process, the oil should flow or stay in the component cavity or pipeline, and different chambers have different pressures, if the oil flows to the cavity or system that it should not flow to, it will cause leakage problems. The leakage problem directly affects the normal operation of the entire hydraulic system. The causes of leakage are divided into internal leakage and external leakage.

(1) The cause of internal leakage: (1) the deviation of processing accuracy caused by running wear; (2) There is a problem with the installation of the sealing part and the sealing ring during assembly, and the damage occurs; (3) The choice of sealing type and sealing ring material is unreasonable.

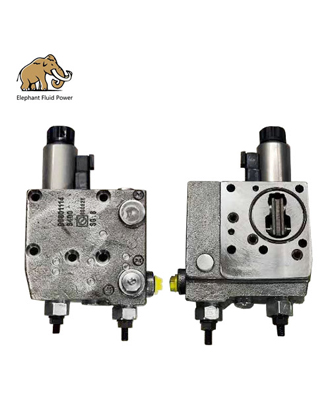

(2) The cause of external leakage: (1) When the hydraulic system is subject to vibration or shock, the hydraulic pipe joint is loose; (2) The seal aging of the hydraulic system during operation, resulting in poor sealing; (3) The hydraulic components form wear during the fitting process; (4) The hydraulic components are in a high-temperature and high-pressure environment for a long time to deteriorate the sealed rubber. Elephant Fluid Power has premium kawasaki parts for sale. If you take interest in our products, do contact us.

4. Noise problem

Noise is a kind of pollution, but also a kind of pollution, the main sound source of noise in the hydraulic system is the hydraulic pump. The mechanical vibration and oil pulsation generated by the hydraulic pump are mainly caused by the noise of the hydraulic pump. These vibrations and pulsations affect not only the hydraulic pump itself, but also other parts of the hydraulic system, such as tanks and circuits, which in turn can induce greater noise.

If these problems occur, you need to pay special attention and timely maintenance, otherwise it is not only possible for small problems to accumulate into large problems and eventually lead to product scrapping, but also may damage the life and health of users, more than worth the loss.

Choosing the kawasaki k3v112dt hydraulic pump from Elephant Fluid Power will save you a lot of trouble with later use and repairs. First of all, the biggest feature of the products produced by Elephant Fluid Power is good quality and high cost performance. Different from ordinary small factories, Elephant Fluid Power has enough venues, funds and talents to ensure the stable production and research and development of products, and it is precisely because of this that Elephant Fluid Power's products have fewer problems and longer service life. Secondly, Elephant Fluid Power all products have a one-year warranty period, even if there is a problem with the product you do not have to worry, Elephant Fluid Power will help you solve it in time, if you are interested, please contact us!

kawasaki k3vl 140 pump

kawasaki k3vl80

kawasaki hydraulic pump usa

k3vl80

kawasaki hydraulic pump distributors

kawasaki pump parts

kpm pump

k3vls65

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu