Elephant Fluid Power company has superb theoretical knowledge and rich practical experience in the field of hydraulic expertise, is a company integrating production and maintenance, sales and product research and development, and has unique experience in the maintenance of nachi hydraulic pump.

As we all know, the hydraulic piston pump parts is the power system of most mechanical equipment, for the machinery, the strong transmission system affects the efficiency and quality of the equipment, in the process of using the equipment we must pay special attention to the maintenance of the hydraulic pump.

The maintenance of the hydraulic pump is mainly the correct use and management of the pump, timely handling of abnormal situations in operation, filtering the working medium, and troubleshooting small faults in order to improve the use of the hydraulic pump in time, ensure the normal operation of the hydraulic pump, and extend the service life of the hydraulic pump. The main reasons for the damage of the hydraulic pump are: wear, corrosion and fatigue damage of the parts in the hydraulic pump; Manufacturing factors or accidents of hydraulic pumps, etc. The essence of repairing a pump damage caused by a normal or abnormal cause is to compensate for its inferiority. There are two basic ways to repair hydraulic pumps: repair and replacement. The main principles of selecting a hydraulic pump are the type of main equipment: the main factors to consider when selecting a hydraulic pump are the structural form, working pressure, flow, speed, efficiency, quantitative or variable, variable mode, life, prime mover type, noise, pressure volatility, self-priming ability, compatibility. Hydraulic oil, size, quality, economy and maintenance.

So how exactly do you repair the nachi hydraulic pump? The first is lubrication, all moving parts should be regularly coated with high-quality molybdenum disulfide or corresponding grease, in mixed environmental conditions, cleaning and lubrication work should be carried out frequently. The second is the hydraulic tubing, after each work, you should check whether there is a break and leak, and regularly clean the dirty joints. The third is the quick coupling, the joint should be kept clean, not allowed to drag along the ground, very small dust may lead to the failure of the internal check valve, sealed with high-quality sealing material. The fourth is the spring, the spring installed between the driving pawl and the reaction paw, if it is capable, it is best to check and replace it once every two years. The fifth is the cylinder seal, if a leak is found, it is recommended to replace the sealing ring and the components that produce deformation. Finally, the structural parts, the structural parts of the tool, should be checked once a year to determine whether there are fractures, defects, deformations, if there are these conditions, need to be replaced immediately.

Nachi hydraulic pump to regular repair, replacement of old devices, in order to extend the life, Elephant Fluid Power company has a very deep experience in this convenience, the hydraulic pump maintenance work to Elephant Fluid Power company will be satisfied with you!

Nachi hydraulics catalog

Nachi pump distributor

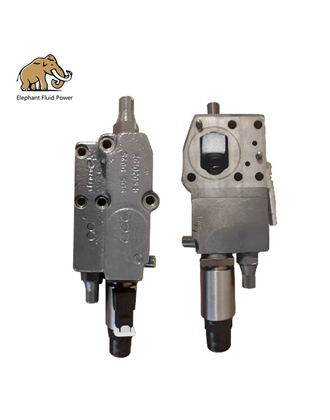

Nachi hydraulic pump parts

Nachi piston pump distributor

Nachi hydraulic pump distributor

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu