In the world of hydraulics, innovation is a driving force that continually shapes the capabilities of hydraulic systems. Small hydraulic piston pumps, in particular, have undergone significant advancements that enhance their efficiency, performance, and versatility. In this blog, we will explore some of the innovations that have propelled small hydraulic piston pumps into the modern age.

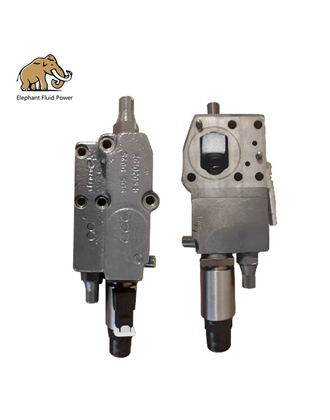

Miniaturization and Compact Design

Advancements in manufacturing techniques and materials have enabled the miniaturization of small hydraulic piston pumps. These pumps can deliver impressive power within a remarkably compact form factor. This miniaturization opens up new possibilities for applications where space is at a premium, allowing engineers to design more compact and efficient systems.

High-Efficiency Pump Designs

Efficiency is a key focus in modern hydraulic systems, and small hydraulic piston pumps are no exception. The design of these pumps has evolved to maximize both volumetric and mechanical efficiency. This efficiency not only reduces energy consumption but also minimizes heat generation, contributing to the longevity of the pump and the overall system. The integration of variable displacement technology into small hydraulic piston pumps has revolutionized their versatility. Variable displacement pumps adjust their output to match the demand of the system, resulting in energy savings and improved control. This technology is particularly beneficial in applications where the load varies over time.

Smart Integration and IoT

Small hydraulic piston pumps are joining the trend of smart integration and the Internet of Things (IoT). These pumps can now be equipped with sensors and electronic controls that provide real-time data on parameters such as pressure, temperature, and performance. This data can be transmitted to central control systems or the cloud for analysis, allowing for remote monitoring, predictive maintenance, and optimization of system performance. As sustainability gains importance, small hydraulic piston pumps are being designed with eco-friendly solutions in mind. Some pumps are engineered to reduce energy consumption and emissions, contributing to a greener operation. Additionally, the use of biodegradable hydraulic fluids aligns with environmentally conscious practices.

Modern small hydraulic piston pumps offer a high degree of customization and adaptability. Manufacturers are providing options for different pump configurations, control mechanisms, and materials. This flexibility allows engineers to tailor the pump to the specific requirements of their applications, optimizing performance and efficiency. The evolution of small hydraulic piston pumps showcases the transformative power of innovation. From compact designs to high-efficiency technologies and smart integration, these pumps have advanced to meet the demands of the modern era. As industries continue to evolve, small hydraulic piston pumps will likely remain at the forefront of hydraulic system design, delivering efficient and precise power in applications across various sectors.

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu