The K3V hydraulic pump is a variable - displacement axial - piston pump of swash - plate design produced by Kawasaki. Here is an introduction to it:

Structural features

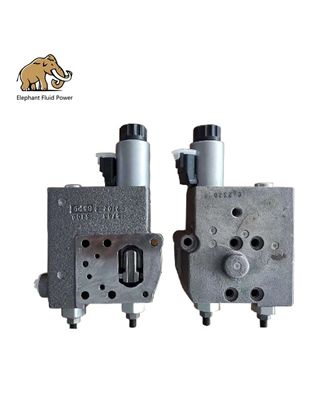

1. Axial - piston swash - plate structure: The piston is arranged axially with respect to the drive shaft, and the swash - plate angle can be adjusted to change the displacement of the pump. It consists of main components such as a cylinder block, pistons, a swash - plate, a valve plate, and a drive shaft.

2. Dual - pump tandem design: It often adopts a dual - pump tandem structure, and can be equipped with a gear pump in series for pilot control. This design can meet the requirements of different working conditions and improve the overall performance of the hydraulic system.

Working principle

The drive shaft drives the cylinder block to rotate. As the cylinder block rotates, the pistons, which are connected to the swash - plate through slippers, reciprocate in the cylinder bores. When the swash - plate angle changes, the stroke of the pistons changes, thereby changing the volume of oil sucked and discharged by the pump, achieving variable - displacement control.

Technical characteristics

1. High power density: It can provide high - power output in a compact structure, suitable for applications where space is limited but high power is required.

2. High efficiency: It has high - energy conversion efficiency, which can effectively convert input power into hydraulic power output, reducing energy loss.

3. Wide range of control options: It offers a variety of control methods, such as negative - flow control, positive - flow control, power control, and two - stage - flow control, which can meet the different working requirements of various equipment.

4. High suction capability: It has strong suction ability, which can ensure the stable supply of hydraulic oil and the reliable operation of the pump even under difficult oil - suction conditions.

5. Good reliability and durability: Made of high - quality materials and advanced manufacturing processes, it has good reliability and long service life, which can withstand the harsh working environment and long - term operation of construction machinery.

Application scenarios

K3V hydraulic pump is widely used in various mobile machinery and equipment, such as excavators, wheel loaders, crawler drills, pile drivers, cranes, and concrete pumps. It is also used in industrial machinery such as crushers and presses, as well as in marine and offshore equipment and mining equipment to provide reliable hydraulic power.

Kawasaki K3VI pump

Swash plate pump K5V

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu