1. Working principle of hydraulic pump

The working principle of the hydraulic pump is that the movement brings about a change in the volume of the pump cavity, thereby compressing the fluid so that the fluid has pressure energy. The necessary condition is that there is a change in the sealing volume of the pump cavity.

A hydraulic pump is a hydraulic component that provides pressurized liquid for hydraulic transmission, and is a type of pump. Its function is to convert the mechanical energy of power machines (such as electric motors and internal combustion engines) into liquid pressure energy. Its cam is rotated by an electric motor. When the cam pushes the plunger to move upward, the sealing volume formed by the plunger and the cylinder is reduced, and the oil is squeezed out from the sealing volume and discharged to the required place through the one-way valve. When the cam rotates to the descending part of the curve, the spring forces the plunger downward to form a certain degree of vacuum, and the oil in the tank enters the sealing volume under the action of atmospheric pressure. The cam makes the plunger rise and fall continuously, the sealing volume decreases and increases periodically, and the pump continuously absorbs and discharges oil.

There are many factors affecting the service life of the hydraulic pump, in addition to the design and manufacturing factors of the pump itself, the selection of some parts of hydraulic piston pump related to the use of the hydraulic pump (such as couplings, oil filters, etc.), and the operation during the commissioning process are also related.

2. What are the classifications of hydraulic pumps?

Types of pumps in hydraulic system: 1. According to whether the flow can be adjusted, it can be divided into: variable pump and quantitative pump. The output flow of hydraulic piston pump can be adjusted according to the needs called variable pump, the flow can not be adjusted called quantitative pump. 2. According to the pump structure commonly used in hydraulic system, it is divided into three types: gear pump, vane pump and plunger pump.

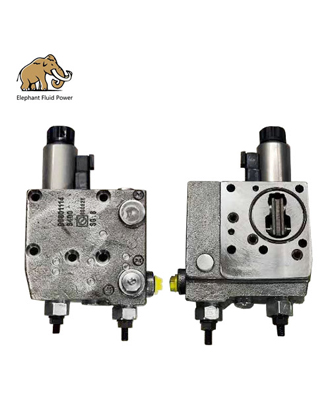

Gear pump: small in volume, simple in structure, less strict on oil cleanliness, and cheaper in price; but the pump shaft is subject to unbalanced force, serious wear, and large leakage. Vane pump: divided into double-acting vane pump and single-acting vane pump. This kind of pump has uniform flow, stable operation, low noise, higher working pressure and volumetric efficiency than gear pump, and more complicated structure than gear pump. Plunger pump: high volumetric efficiency, small leakage, can work under high pressure, mostly used in high-power hydraulic systems; but complex structure, high requirements for materials and processing accuracy, high price, and high requirements for oil cleanliness. Piston pumps are generally used when gear pumps and vane pumps cannot meet the requirements. There are some other forms of hydraulic pumps, such as screw pumps, etc., but the application is not as common as the above three.

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu