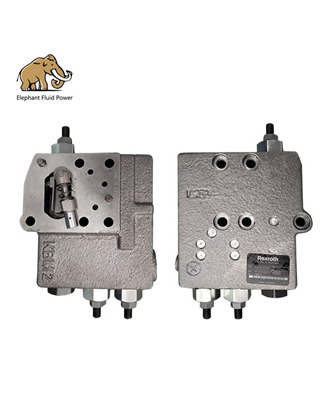

Hydraulic valves are the most widely used component in hydraulic systems. Its function is to control the flow direction, pressure and flow of oil to meet the power direction, force (or torque) and rate requirements required by the actuator, so that the entire hydraulic system can work in harmony as required. Therefore, when the hydraulic valve fails, it has a great impact on the stability, accuracy and reliability of the hydraulic system, and even causes the system to not work at all.

The analysis of the cause of the failure of the hydraulic valve cannot be simply equivalent to the analysis of the failure cause of the general mechanical components, it also has the factors of the hydraulic components themselves. Elephant Fluid Power lists several common signs of hydraulic valve failure to prevent hydraulic equipment management in the bud.

(1) Damage

The moving pairs of hydraulic valve cores, valve sleeves, valve bodies and other mechanical parts are constantly rubbed during use, resulting in changes in the size, shape and surface quality of the parts. Damage or deformation of the valve core of the electromagnetic reversing valve will cause leakage in the valve, reduce the efficiency, and the dirt will easily enter the gap or deform, resulting in mechanical blockage of the valve core. If the mating gap between the spool and the valve orifice is too large, a pressure shock will occur. Damage to the pilot valve of the pressure regulating valve can make the valve work unstable or even unable to adjust the pressure. Due to wear, the main poppet valve (or main ball valve) of the speed regulating valve is not tightly sealed and the pressure cannot be adjusted normally. The check valve of the check throttle (speed regulation) valve is partially damaged, the seal is not strict, and part of the oil flow flows through the check valve, which affects the sensitivity of speed regulation.

(2) Exhaustion

Working under long-term variable load, the spring in the hydraulic valve will soften due to fatigue, and the spring length will be shortened or broken as a whole; Spools and seats can also crack, fall off, or otherwise be damaged by fatigue. All of this can lead to valve failure. Spring fatigue or breakage on the main spool or pilot valve of the speed regulating valve can cause the system pressure to fall short of the requirements. The spring of the directional valve is too soft or too short will affect the working position and normal return of the valve core, so that the system cannot work normally.

(3) Deformation

When the residual stress and external load stress of hydraulic valve parts during processing exceed the yield strength of the part material, the parts are deformed, unable to complete normal functions, and faulty. The bending deformation or spring deformation of the speed regulating spool will make the spool move inflexibly, resulting in unstable system pressure. The bending deformation of the unloading spool will slow down the movement of the spool and slow down the conversion process of the system from unloading to working pressure or working pressure to unloading pressure. The bending and deformation of the spool of the directional valve will make it difficult to carry out the reversing action normally. Please note that improper installation may also cause parts to deform. For example, body deformation caused by overtightening of the directional valve mounting screws may block the spool.

(4) Corrosion

Mixing hydraulic oil with too much water or acidic substances will corrode the relevant parts of the hydraulic valve after long-term use and lose its due accuracy.

After a long period of use, problems are inevitable after hydraulic valve, and timely detection of problems and replacement of related parts can effectively extend the service life of the product. Hydraulic valve is a high-precision mechanical product, without the guidance of professional and technical personnel, please do not disassemble at will, such behavior may cause secondary damage to the product.

All products manufactured by Elephant Fluid Power come with a one-year warranty, during which you can get full technical support to help you solve the problem of using the product. Moreover, Elephant Fluid Power also produces suitable components, which are made of high-quality materials, have a long service life and are 100% compatible with the original. Elephant Fluid Power is a professional hydraulic products production company, all their employees are professionally trained, can solve customer problems efficiently, a number of professional production lines also ensure the rapid and high-quality production of products.

What's more, the hydraulic products produced by Elephant Fluid Power are very cost-effective, and the highest quality products are obtained at the best price, and the customers who have worked with them are full of praise.

If you have any related needs, please contact us.

hydraulic control valve problems

troubleshooting hydraulic valves quizlet

how to troubleshoot hydraulic systems

hydraulic control valve troubleshooting

hydraulic troubleshooting basics

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu