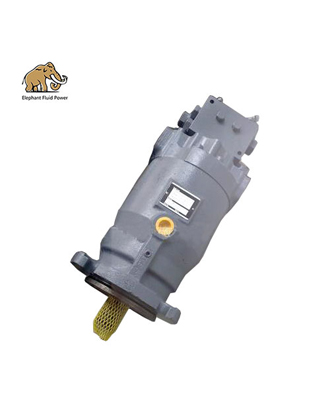

A2FM motor is a high-performance inclined shaft axial piston quantitative motor produced by Rexroth, which is widely used in the fields of construction machinery, industrial equipment, etc. The following is an introduction of core features, technical parameters, application scenarios and maintenance points:

First, core features

1、Slanted shaft structure design

Adopting inclined shaft axial piston quantitative motor design, the piston is arranged at an angle with the drive shaft, and the reciprocating motion of the piston in the cylinder realizes the conversion of hydraulic energy to mechanical energy. This structure enables the motor to maintain stability and reliability under high pressure and high speed conditions, and is suitable for open and closed hydrostatic transmission circuits.

2、High power density and efficiency

High power density: in the same volume can output more torque, suitable for equipment with strict requirements on space and weight (such as excavators, cranes).

High total efficiency: high initial efficiency, excellent hydraulic-mechanical efficiency (ηhm) and volumetric efficiency (ηv), low energy loss and reduced energy consumption.

3、Compact and durable design

Short installation height: compact structure, easy to be arranged in limited space, suitable for construction machinery and other occasions requiring high installation dimensions.

Strong abrasion resistance: key components (such as plunger, cylinder, flow distribution disk) are made of high-strength materials, adapting to harsh working environments (such as mines, construction sites) and prolonging service life.

4、Flexible control and adaptability

Adjustable output speed: By adjusting the pump flow and motor displacement, the output speed can be precisely controlled to meet the demands of different working conditions.

Torque and differential pressure: the torque increases with the pressure difference between high and low pressure sides and the displacement, providing strong power output.

Multiple pressure ranges: 3 pressure ranges (e.g. 300bar, 400bar, 450bar) are available to meet different load requirements.

Second, technical parameters

1、Displacement and speed

Displacement range: 44.9cm³/r (A2FM45) to 108.8cm³/r (A2FM107), some models have larger displacements (such as A2FM160).

Nominal speed: 3,000rpm to 5,000rpm, the maximum speed can reach 5,500rpm, to meet the needs of high-speed operation.

2、Pressure and torque

Nominal pressure: 300 bar to 450 bar, the maximum pressure can reach 500 bar, to adapt to heavy-duty working conditions.

Output torque: under nominal pressure, the torque ranges from 270Nm (A2FM56) to 648Nm (A2FM107), providing strong power.

3、Efficiency and response

Volumetric efficiency: the volumetric efficiency of the new pump is ≥95%, and it should be ≥85% after 2,000 hours of use, ensuring efficient energy conversion.

Angular acceleration: the maximum angular acceleration can reach 19800rad/s² (A2FM80), rapid response, suitable for dynamic loads.

Third, Application Scenarios

1、Construction Machinery

Excavator: Drive the slewing mechanism and traveling device to provide high torque and precise control.

Concrete mixer/pump truck: Realize mixing and pumping action, adapt to heavy load and continuous operation.

Paver/Crane: Provide stable power output to ensure smooth operation of the equipment.

2、Industrial equipment

Injection molding machine: drive the hydraulic system to realize the opening and closing of the mold and injection action.

Metallurgical equipment: such as rolling mills and continuous casting machines, providing high torque and precise control.

Mining machinery: such as roadheader, coal mining machine, to adapt to the harsh environment and heavy-duty working conditions.

Fourth, maintenance points

1、Fluid Management

Viscosity requirements: the viscosity of hydraulic fluid ranges from 10mm²/s to 400mm²/s (at 40℃), HLP mineral oil is recommended.

Cleanliness requirements: According to ISO 4406 standard, the cleanliness should be kept at least 20/18/15 level, the finer the filter element, the higher the cleanliness of the hydraulic oil, the longer the service life of the axial piston unit.

Oil change cycle: Replace the hydraulic oil and filter element regularly to prevent oil contamination leading to component wear.

2、Operation monitoring

Oil temperature monitoring: normal operating temperature 50℃ to 70℃, over 80℃ need to check the cooling system or load condition.

Pressure monitoring: check the pressure of high pressure side and low pressure side regularly to prevent the pressure difference from being too large and causing damage to the parts.

Vibration monitoring: Vibration is monitored by acceleration sensor, abnormal vibration may indicate bearing or gear failure.

3、Component Inspection and Replacement

Seal inspection: Regularly check the aging condition of seals and replace them in time to prevent leakage.

Plunger and cylinder: check the plunger clearance and cylinder wear, adjust or replace parts.

Distributor disk: check the wear and sealing of distributor disk, grind or replace if necessary.

Bosch rexroth A2FM

Rexroth A2FM specs

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu