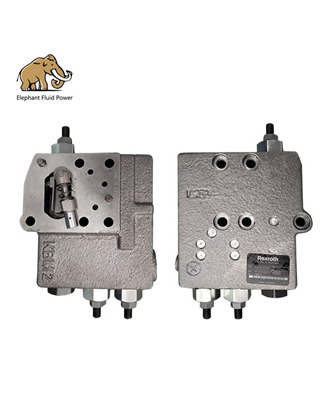

The A6VM is an axial piston variable displacement motor commonly manufactured by companies such as Bosch Rexroth, with widespread application in fields like construction machinery.

First, Working Principle

The A6VM motor achieves stepless displacement adjustment by altering the stroke length of the pistons through changes in the swashplate's tilt angle. When hydraulic fluid enters the piston bore, the piston extends outward under pressure. The reaction force from the swashplate splits into axial and vertical components, with the vertical component generating torque to drive motor rotation. Adjusting the swashplate tilt angle alters the piston stroke length, thereby controlling the motor's displacement and output torque.

Second, Product Features

1. Multiple Displacement Options: Covers a wide range of displacement specifications, allowing selection of the appropriate displacement for different application requirements. Enables stepless adjustment to meet torque and speed demands under various operating conditions.

2. High Efficiency and Energy Savings: Maintains high efficiency under different loads through precise displacement control, reducing energy consumption.

3. High Reliability: Constructed with durable materials and advanced manufacturing techniques, it offers exceptional reliability and extended service life, capable of withstanding harsh operating environments.

4. Flexible Control: Compatible with multiple control methods to achieve precise speed and torque regulation.

Third, Application Scenarios

The A6VM motor is suitable for various industrial and mobile equipment demanding high hydraulic system performance, including but not limited to:

1. Construction Machinery: Such as excavators, loaders, and cranes, driving working devices to achieve precise motion control.

2. Agricultural Machinery: Such as harvesters and seeders, providing power for various working implements.

3. Industrial Equipment: Also applied in industrial machinery requiring precise control and efficient power transmission.

Fourth, Maintenance Precautions

1. Safety First: Strictly adhere to safety protocols during maintenance to prevent accidents. For instance, use appropriate tools when relieving system pressure and guard against hydraulic fluid spray injuries.

2. Clean Environment: Maintain a clean workspace to prevent dust and contaminants from entering the motor and compromising performance.

3. Professional Tools: Use specialized maintenance tools to prevent damage to components during disassembly and assembly.

4. Hydraulic Fluid Management: Replace with clean hydraulic fluid promptly after maintenance and conduct regular fluid quality checks to ensure compliance with specifications.

Elephant Fluid Power operates three specialized production lines, consistently upholding a “Quality First, Customer First” philosophy. Our clientele spans over 30 countries worldwide. For your hydraulic product needs, choosing us will never disappoint.

A6VM motor

rexroth a6vm service manual pdf

a6vm rexroth pdf

a6vm160

a6vm200

a6vm250 rexroth pdf

rexroth a6vm series 71

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu