The hydraulic brake system is mainly composed of the following components. Energy supply device: includes various components that supply, adjust the energy required for braking, and improve the state of the transmission medium. Control device: Various components that produce braking action and control the braking effect, such as brake pedals. Transmission: including the transmission of braking energy to various components of the brake, such as brake master cylinder, wheel cylinder. Brake: A component that creates a tendency to impede the movement or movement of the vehicle.

The braking system is generally composed of two main parts: brake control mechanism and brake. Its general working principle is to use the mutual friction between the non-rotating elements connected to the body (or frame) and the rotating elements connected to the wheel (or propeller shaft) to stop the tendency of the wheel to turn or turn. That is, when the brake pedal is pressed, the piston of the main cylinder is pushed forward, the pressure of the brake fluid in the main cylinder increases, and the sub-pump of each wheel enters through the oil pipe, and the piston of the sub-pump is pushed outward, so as to realize the transmission of the force of the foot brake to the wheel brake, and push the wheel brake to brake. When the brake pedal is released, the main pump piston returns under the action of oil pressure and return spring, and the sub-pump piston and wheel brake brake return to position and release the brake on the wheel.

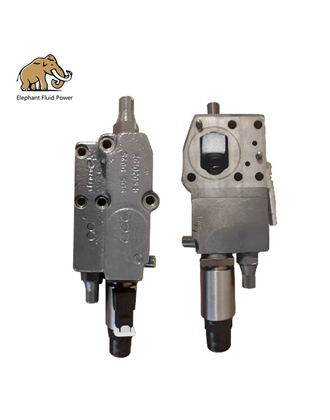

When the brake pedal travel is too long, the driver will obviously feel poor braking performance, no confidence in the braking ability of the whole vehicle, and at the same time increase the driver's fatigue and not meet the ergonomic design requirements; The brake pedal stroke is too short, the whole vehicle brakes roughly, and the passenger's forward tilt is serious when braking, and the comfort is reduced. Therefore, in order to improve the braking performance of the car, it is necessary to choose high-quality hydraulic system components. If you have a need, why not take a look at our Elephant Fluid Power offerings. Elephant Fluid Power is a hydraulic company with rich production experience, they have a fairly mature production process and large-scale production base and strong production capacity, which can easily meet the production of different brands and series of hydraulic product accessories. The parts we produce are made of the best quality non-ferrous metal raw materials, the production process follows strict quality inspection standards, German CNC production equipment ensures that all the products they produce are of uniform quality, and there will be no inferior products that do not meet the standards.

Choosing our elephant fluid power will bring you the most satisfying buying experience, and I am sure that we will become your most trusted partner.

hydraulic brake system pdf

brake system components diagram

brake system components pdf

hydraulic brake diagram

hydraulic brake system parts and function

Hydraulic braking system

functions of hydraulic brake system

hydraulic brake parts mtb

French

French

Portuguese

Portuguese

Russian

Russian

German

German

Spanish

Spanish

Japanese

Japanese

Korean

Korean

Irish

Irish

Greek

Greek

Turkish

Turkish

Italian

Italian

Danish

Danish

Romanian

Romanian

Indonesian

Indonesian

Czech

Czech

Afrikaans

Afrikaans

Swedish

Swedish

Polish

Polish

Basque

Basque

Catalan

Catalan

Esperanto

Esperanto

Hindi

Hindi

Lao

Lao

Albanian

Albanian

Amharic

Amharic

Armenian

Armenian

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Cebuano

Cebuano

Chichewa

Chichewa

Corsican

Corsican

Croatian

Croatian

Dutch

Dutch

Estonian

Estonian

Filipino

Filipino

Finnish

Finnish

Frisian

Frisian

Galician

Galician

Georgian

Georgian

Gujarati

Gujarati

Haitian

Haitian

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hmong

Hmong

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourg

Luxembourg

Macedoniar

Macedoniar

Malagasy

Malagasy

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Burmese

Burmese

Nepali

Nepali

Norwegian

Norwegian

Pashto

Pashto

Persian

Persian

Punjabi

Punjabi

Serbian

Serbian

Sesotho

Sesotho

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Samoan

Samoan

Scots Gaelic

Scots Gaelic

Shona

Shona

Sindhi

Sindhi

Sundanese

Sundanese

Swahili

Swahili

Tajik

Tajik

Tamil

Tamil

Telugu

Telugu

Thai

Thai

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Xhosa

Xhosa

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu